SHARING KNOWLEDGE EXPERIENCE AS THE KEY TO SUCCESS

BLOG

SHARING KNOWLEDGE EXPERIENCE AS THE KEY TO SUCCESS

BLOG

SHARING KNOWLEDGE EXPERIENCE AS THE KEY TO SUCCESS

The object of this blog is to explore methods for garment factories to have competitive advantage for long term sustenance.

Most of the garment factories work on the principle that the overall efficiency / productivity will increase

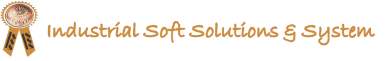

Managing and improving productivity needs to effectively use the resources manpower, machines etc, and the main problem

Operations research is an analytical method, where a real problem is converted to a maths problem by certain assumptions

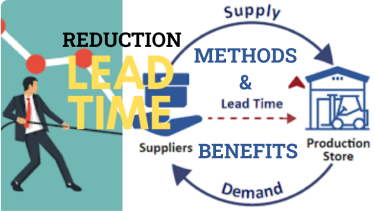

One of the main reason for low productivity is the time& effort of the workers involved in transporting, positioning and handling

Management reports – MIS helps to identify issues, planning targets, aligning various departments and improving profitability.

With the garment industry spending close to 15% of sales turnover on cost of quality; the industrial engineer has got a big role

The advantage of dynamic programming is that it can obtain both local and total optimal solution. Also, practical knowledge

In the overall digitisation process, each individual operation digitisation, gives enormous benefits. Unlike the engineering industry,